Eel Seals

So smooth it can only be described as slippery. This latest innovation from Universal Seal features a near frictionless dynamic seal face able to tolerate the most pitted and abrasive shaft surfaces. Trouble literally passes effortlessly across the surface doing less harm, giving the seal a longer wear life.

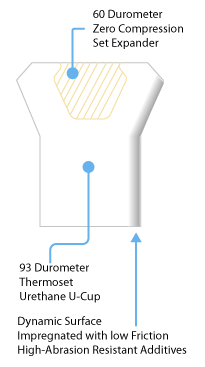

Each highly energized eel-seal features a high volume, virtual zero compression set expander capable of maintaining a high radial force on the shaft for effective low pressure sealing throughout the extended life of the seal.

The eel-seal is premium cast urethane loaded lip rod seal. Then energizer element, which has virtually zero compression set, is cast in place and chemically to the inside of the u-cup resulting in a single piece dual durameter seal. This unique design permits 95% more energizer volume than provided by an ordinary 'o'ring insert, and the unique filler cannot pop out or extrude in service.

But this is not even the eel seal's most unique feature . We also deeply impregnate the dynamic contact area with a special low friction additive creating slippery, slightly hardened and highly abrasion resistant surface.

These features combine to provide a seal with an extended life in even the most demanding conditions.

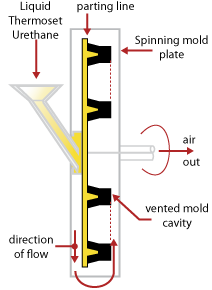

Centrifugal Molding

The centrifugal molding process is the only process capable of producing this uniquely effective seal. And this revolutionary process is available only through Universal Seal . Details.Material Specifications |

||||

|---|---|---|---|---|

|

Property |

Units |

ASTM Test Method |

U-Cup Material |

Expander Material |

Hardness |

SHORE A | D 2240 | 93 | 60 |

Modulus (100%) |

PSI | D 412 | 1400 | 299 |

Tensile Strength |

PSI | D 412 | 5800 | 452 |

Elongation |

% | D 412 | 420 | 154 |

Split Tear |

lb./in. | D 470 | 100 | 7.3 |

Die C Tear |

lb./in. | D 624 | 430 | - |

Compression Set |

% | D 395B | 24 | < 1< |

Bashere Rebound |

% | D 2632 | 45 | 46 |

Service Temperatures |

|

|---|---|

Minimum |

- 40° F |

Maximum in oil based fluids |

200° F |

Maximum in water based fluids |

120° F |

Roughness |

|

|---|---|

Dynamic Sealing Face |

4 to 32 u inches |

Static Sealing Face |

4 to 63 u inches |

Static Gland Faces |

4 to 125 u inches |

Maximum Working Pressure |

|||||

|---|---|---|---|---|---|

Pressure (PSI) |

Max Extrusion Gap (inches) |

Maximum Speed (ft/sec) as Temp

|

|||

| 3000 | 0.022 | 1.5 | 1.5 | ||

| 4000 | 0.018 | 1.5 | 1.0 | ||

| 5000 | 0.016 | 1.0 | 0.5 | ||

| 6000 | 0.015 | 0.5 | - | ||

The material properties of the Dynamic Surface are modified as follow by the impregnation of a low friction additive: |

|

|---|---|

Hardness is increase: |

from 93 A to 58 D |

Coefficient of friction is reduced: |

from 0.44 to 0.32** |

Abrasion resistance is improved: |

from 70 to 40*** |

|

** on

carbon steel *** DIN 54516 Method - Volume loss (mm³) |

|