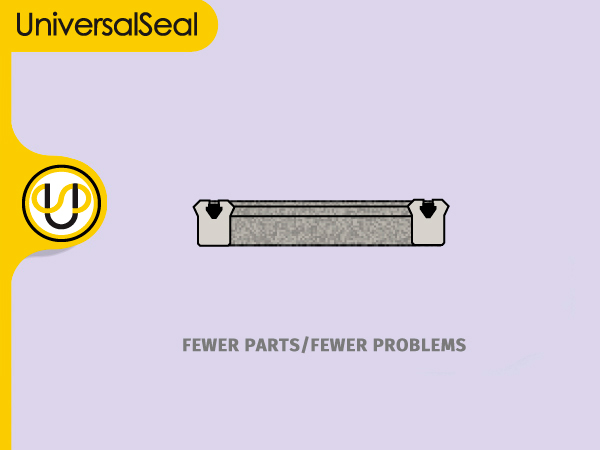

U-Packs

The best all purpose seal for use in standard hydraulic fluids

Characteristics

The U-PACK loaded lip style U cup combines the latest design technology together with the superior field tested technology together with the superior field-tested physical characteristics of a liquid cast polyurethane to produce the best all purpose seal for use in standard hydraulic fluids. Thermosetting Unithane 292A is a Moca cured liquid cast polyurethane which outperforms injection molded grades of polyurethane in all aspects including cut strength, abrasion resistance, compression set and temperature range. The inner elastometric spring element of nirile rubber is designed and strategically positioned to create the necessary lip interference without excessive friction. This energizer is securely held inside the Unithane outer shell so that it will not become disengaged when severely distorted as is sometimes necessary when installing U-Packs on rod seal applications. The nitrile spring element is split prior to assembly to avoid trapped pressure from forcing the spring element outward into the seal cavity during rapid or severe fluctuations of system pressure. The nitrile spring also enhances low temperature sealing characteristics down to -40 degrees F, insures superior low pressure sealing performance and compensates for the gradual wear associated with normal cylinder cycling thereby providing longer service life.

The sealing lips of Series No. 30 U-Packs are knife trimmed to eliminate all molding flash and to provide complete circumferential lip contact which also helps to insure maximum low pressure sealing performances.

Material

- SEAL: Unithane 292A, Liquid Cast Polyurethane, Duro 92A

- ENERGIZER: Nitrile Rubber, Duro 70A

- FLUID COMPATABILITY: See ‘Material Specifications’, Technical Bulletin US 96